|

|

|

West Cobb Engineering And Tool Inc. is a primary industrial resource for the large scale, complex assembly fixtures and jigs used by aircraft manufacturers. We operate modern, well-maintained facility with the resources, efficiency, and flexibility to respond to the growing technology demands and fast pace of the aerospace market.

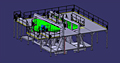

We recently built the cockpit floor assembly jig shown here. It featured overall dimensions of 14' in length, 9.5' in width, and 11' in height, and weighed approximately 5000 lbs. Our strategic investment in rigidly designed and constructed 5-axis machining equipment permitted us to efficiently manufacture the many tight tolerance steel and aluminum component parts of this fixture. For a large, ...

|

|

|

|

|

|

|

West Cobb Engineering And Tool Inc. is at the forefront of aerospace tool design, and one of our specialties is fabricating large aircraft assembly fixtures, such as the one pictured here. Used for securing the major components and modules for accurate, true, and square assembly of the fuselage of a large transport plane, precision quality construction was critical to achieving the unforgivingly tight tolerance requirement of the aircraft assembly operation.

Using multidisciplinary engineering software gave us a full spectrum of tools for designing an ergonomic and productivity-enhancing solution for this complex assembly structure. Featuring overall dimensions of 28.5' in length, 6.5' in width, and 14.0' in height, we ...

|

|

|

|

|

|

|

At West Cobb Engineering And Tool Inc., we have specialized in precision machining for the aerospace industry for over 30 years. A client needed an aft tail cone assembly jig for an aircraft assembly, and our company was a natural fit with our high level expertise and cutting edge equipment. We employed our SNK 250 CNC 5-Axis Machine, Calypso Dual-Head Waterjet, and our MIG welder to machine this assembly from steel tubing. Our Brown and Sharpe 10 40 10 Coordinate Measuring Machine (CMM) and Leica Laser Tracker were used to inspect the headers and set details. The assembly was surface ground for a smooth finish and epoxy painted. When completed, the tail cone assembly jig measured 131.7" in length, 75.1" in width, 32.9" in depth, ...

|

|

|

|

|

|

|

Since 1983, we have been providing custom aerospace products based on customer-supplied designs. At West Cobb Engineering And Tool Inc., our solid reputation is reflected in our AS9100 REV C and ISO 9001:2008 certifications.

For this project, we were contracted by an aerospace customer to manufacture a composite tool for a luggage compartment. Our company was pleased to accept this project, and we began by creating a 2D CAD drawing using our customer's specifications. We employed our Gerber Cutter and vacuum bag molding capabilities to fabricate this tool from Airtech TMFP glass. It was then autoclave cured to Airtech specs, and finished with a Chem-Trend sealer and release system. The completed tool measured 49" in length, ...

|

|

|